Hazheng polylactic acid project: "corn to plastic"

Release time:

2019-11-05

When the traditional plastic products gradually evolved into a "white pollution", we are constantly calling for a green alternative to About Us life.

When the traditional plastic products gradually evolved into a "white pollution", we are constantly calling for a green alternative to About Us life. Pursuing this dream, an innovative team of Haizheng Group has taken root in the laboratory for more than ten years, and finally successfully developed a biodegradable polylactic acid material and promoted the industrialization of this new type of biological material.

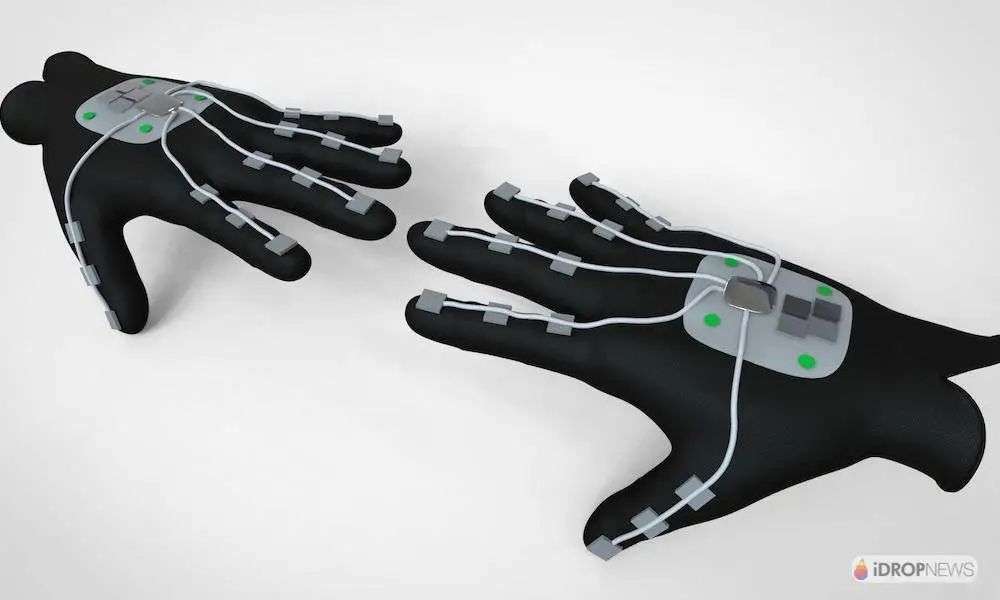

From snack boxes to ordinary water cups to fiber gloves, the daily necessities you see are made of this new type of biological material. When the starch-saturated corn is processed into colorless and transparent liquid lactic acid through modern biotechnology, the granular polymer material polylactic acid is generated through a special polymerization reaction. This polylactic acid is the innovative result of Haizheng Group's test of water biomaterials. The leading product development is the Haizheng Group's polylactic acid research and development and application of science and technology innovation team.

As a traditional API manufacturer, Haizheng Group initiated cooperation with the Changchun Institute of Applied Chemistry, Chinese Academy of Sciences as early as 2000, and decided to carry out related industrialization research in the field of polylactic acid. At that time, the only company in the world that could realize the industrialization of polylactic acid was a NatureWorks company in the United States. This decision of Haizheng Group also gave Bian Xinchao, who had been immersed in the experiment of polylactic acid materials in Changchun Institute of Applied Chemistry, an opportunity.

Bian Xinchao, deputy general manager of Zhejiang Haizheng Biomaterials Co., Ltd.: "For me personally, it is also a good opportunity. We can transfer the results of the laboratory to industrialization. This is one of our scientific researchers. Desire or lifelong pursuit."

After completing the pilot and pilot production, in 2007, the first domestic demonstration production line of polylactic acid with an annual output of 5000 tons was successfully produced in Hazheng. With the operation of this production line, it also marks that China has become the second country in the world to realize the industrial production of polylactic acid. Since then, Haizheng Group has continued to strike while the iron is hot, expanding production capacity all the way, and has now formed a production capacity of 15000 tons of polylactic acid.

Bian Xinchao, deputy general manager of Zhejiang Hazheng Biomaterials Co., Ltd.: "It has taken us 15 years to move our project from the laboratory to a production capacity of 15000 tons."

In Bian Xinchao's view, the course of the past 15 years has not been smooth, even full of risks and tests. In the sea is polylactic acid project officially put into the market soon, a crisis will follow. The polylactic acid products exported by a downstream enterprise actually had serious quality problems when they arrived at the customer's national terminal across the ocean. After investigation, it turned out that the temperature in the highly sealed container during long-distance transportation increased, exceeding the heat resistance point of polylactic acid by 60 degrees, thus causing the thermal deformation of the product. How to improve this defect and improve the heat resistance of polylactic acid has naturally become a difficult problem that Hais polylactic acid research and development team urgently needs to crack.

Bian Xinchao, deputy general manager of Zhejiang Haizheng Biomaterials Co., Ltd.: "This process lasted about two years, and we also invested a lot of energy, manpower, and financial resources, but the good news is that we finally solved this problem. We have overcome it, and we can be regarded as the first in the industry."

Today, the heat resistance point of Hais polylactic acid products has been increased from the original 60 degrees to 120 degrees, and this performance is even better than foreign products.

It is worth mentioning that at the end of last year, Hazheng Group spent nearly 1 billion yuan on the 50000-ton polylactic acid industrial chain project in the Taizhou Bay Circular Economy Industrial Cluster. After completion, it will become the largest polylactic acid production base in Asia. As the most application development potential of ecological environmental protection materials, the promotion and application of polylactic acid will also lead the transformation and upgrading of Taizhou biomedicine and traditional plastics industry.

Key words:

Mechanical gloves Safety gloves Work gloves